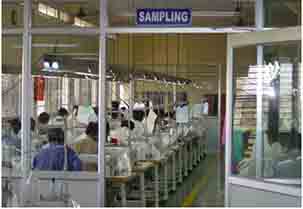

About Sample of HNM Fashion House

New design development is very important for every retailer. For this reason customer need Photo. Salesman, Pre-production & Production sample. Every year buyer develops number of new products, which is full of trial and error. Speed to market is critical to retail business that requires quick support from the supplier. But the supplier always in a rash that’s why many buying house created their own sample development facilities to give quick development support to the buyer. To give prompt support to our customer, We have expert sample team to develop any kinds of sample. Correct sample reduce our production lead time so that we can ready goods before delivery date.

Sampling is important for garments manufacturing process in a textile industry. For this reason garments factories have a garment sampling department. For confirming an export order, sampling plays an important role. According to the sample condition, buyer will give comments. Generally, buyers require different types of sample from different stages of the order process. There are few stages in garments industry for making an export order.

- Fit sample:

For making a fit sample, fashion designers are using dummy. Fit samples are prepared by buyer order sheet measurement. For this reason, fit sample is very important in garments sampling department.

- Photo shoot sample:

When the fit sample is approved the photo shoot sample is made. Taking Photo shoot for the buyer where samples will be worn by the models or dummy. For this sample, actual fabrics and accessories are compulsory. By this sample buyer can easily give their comments.

- Pre-production sample:

The Pre-production sample is the last stage of development sample. In apparel industry, short name of this sample is PP sample. Garment bulk production depends on approval of pre-production sample from buyer. So pre-production sample is a most important sample.

- Size set sample:

Generally a garment has different sizes such as 56, 62, 68, 74, 80, 86, 92, 98, 104, 110, 116, 122, 128, 134, 140, 146, 152, 158, 164, 170, XS, S, L, M, XL, XXL, etc. For this reason, check the fit of the garment in different sizes. Size set sample is very important because without this approval, the cutting should not be started.

- Production samples:

Production samples are the last stage of sampling process at manufacturing industry. Actually, this stage is combustion of online sample and shipment sample. By those samples a buyer can know the bulk production condition of a garment industry. In both stages of production, used original fabrics and accessories.

- Shipment sample:

In this stage production has done. For sending this sample to the buyer, need all packing accessories such as poly, hanger, packing list, bar code sticker, hang tag, price tag, etc. In garment factory, shipment samples are kept for future reference that’s why, this sample is known as keep sample.

- Salesman Sample (SMS):

Sometime buyer needs SMS to increase their order. They show this sample to Retailers. SMS samples are ordered after fit sample approval. And normally prior to size set sample development. SMS sample requirement ordered by buyers and buyer pays to the supplier for SMS samples.

The design of the SMS sample is mostly the same as the final production garments. Salesman samples are made with actual fabric and trims and accessories.

A number of SMS sample requirement is higher than the other sample need. The reason these samples are put on display in the showrooms. Buyer send SMS samples to the retails shops and based the design retailers placed an order on that particular order. Buyer later forecasts order quantity on that particular design based on the customer feedback and order placed by their retailers.