Production

We mean production – all the process from making fabrics to closing cartoons. Its start continued until shipment after approved PP sample. It is comprehensively detailed. The following are the steps:

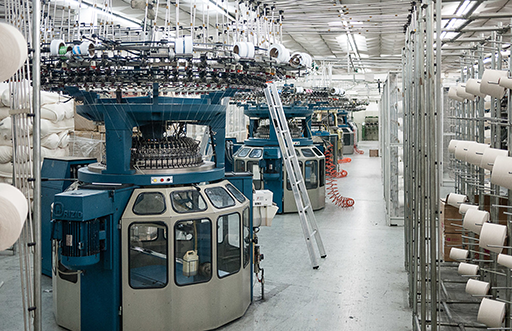

1. Yarn Collect 2. Knitting

3. Dyeing 4. Cutting

5. Printing / Embroidery 6. Accessories

7. Sewing 8. Quality Checking

9. Ironing 10. Packing

My teams strictly follow up those sections with factory’s every unit.

Garments Production Planning and Order Follow Up:

Production Plan establishes is vital role for on time delivery. We have separate section to follow up production who are follow up every section. After we confirm the order, we specify the time of delivery and follow up with timely delivery. We take production update time to time from factory like as given their T&A.

Export order follows up in apparel industries in key role for order execution. As we know that once an order is confirmed we have a time limit for order execution. When we executed order in time limit as time provided by the buyer then we have become a good exporter for buyer and faith of buyer over exporter is increased as he told to buying house please placed order to this exporter his execution time good for us.

Once order shipped on time we have created a long term relationship with the buyer. This relationship has an advantage and we created faith over buyer, thus buyer given more order due to the cause of this we have a drawback in apparel industries. As this is also creating a faith of yarns, trims and accessories suppliers as these all suppliers have faith over exporter to he has a good order, thus his payment term is good so they have entrusted to supply these all. Buying house also has faith over exporter and if any new buyer approaches for an order to buying a house, then buying house without any doubt place order.

Once an order is confirmed we start analyzing the sample and as per sample, we have given a T& A to buyer. This T&A have a time limit for order confirmation till order execution. Just like for example if we have basic style, then we generated a time limit for lab dip submission, fit submission, size set submission, pre-production sample submission, lab dip approvals, yarn submission date after lab dip approval, trims date submission, accessories date submission, knitting start to end date, CMT starts to end date, finishing start to end date, packing starts to end date.

- Very close monitoring of all steps in the production process is vital to ensure punctual shipments and avoid “unpleasant surprises” like expensive air-freights, short shipments or even cancellations.

- We have fine-tuned our production status & process reporting system which enables our experienced merchandising and QC staff to easily detect arising problems at a very early stage and initiate immediate actions.

- HNM Fashion House reliability and proven performance over many years is reflected by our long term customers.

- We specialize is in timely shipment and exceptional quality, all at a competitive price. Our experienced employees work tirelessly to help us maintain this specialty.